-

-

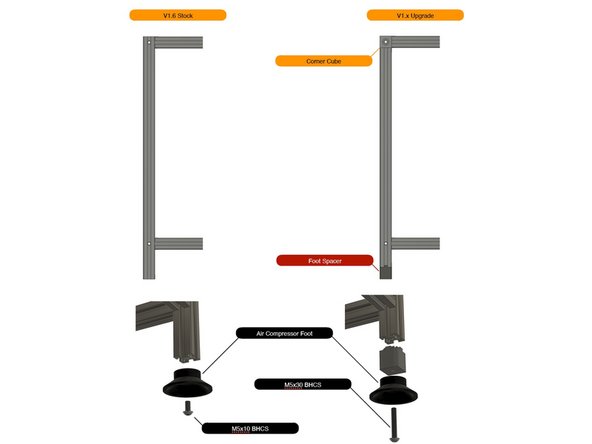

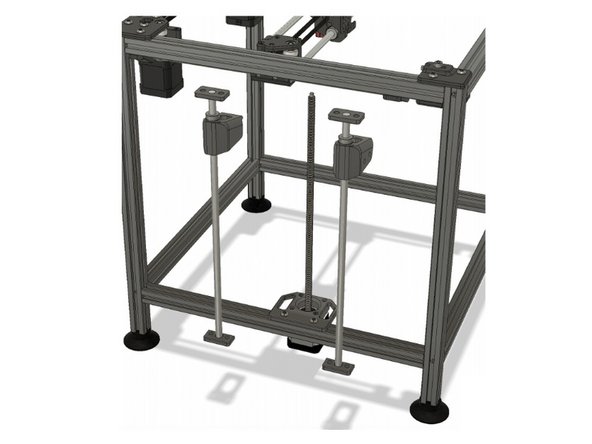

Make note of the vertical extrusions if you are upgrading or doing a new build.

-

-

-

Build your frame on a flat surface to help square your frame. Granite countertops work well. Other tools such as a machinist square will work well too.

-

Loctite is not required on the joints but can be added for extra peace of mind.

-

-

-

Include the extra spacers if you are upgrading from an early V1 build.

-

-

-

Check that your completed frame is square.

-

Frame should not rock or wobble on a flat surface.

-

Measure diagonals and remove any variance as much as possible.

-

-

-

It's easiest to run a flat down the length of the entire 5mm shaft.

-

The flat only needs to be deep enough for the grub screw to catch and not slip.

-

When your pulleys are in place, be sure to loctite your grub screws.

-

-

-

Add the drive stacks to the printed pieces along with another 20t pulley to lock the stack into place.

-

-

-

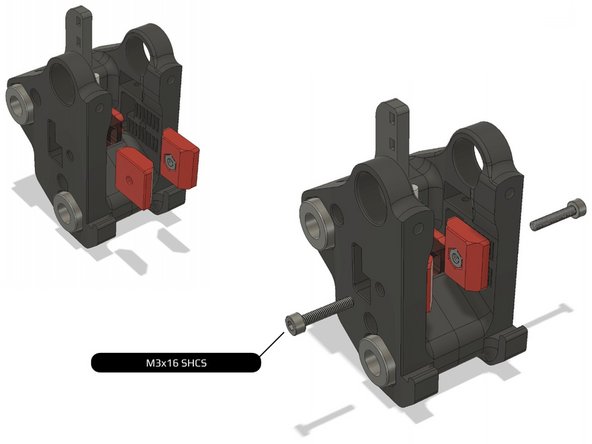

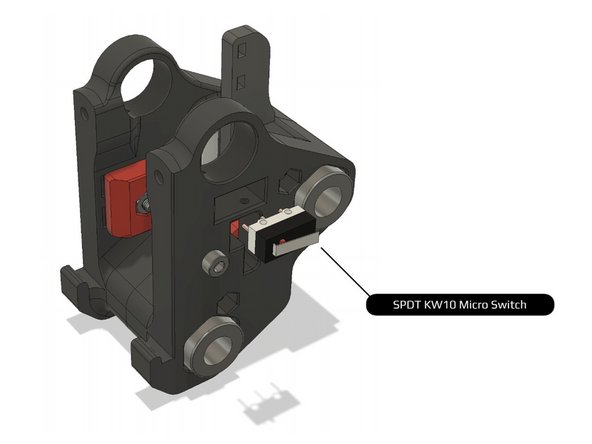

Be sure to wire the micro switch as NC (Normally Closed). On most switches this means connecting wires to the outer two terminals on the switch, but you can check with a multimeter by making sure there is continuity at those pins when the switch is not pressed.

-

Add a vertical line to the 20t pulleys in each stack so you can troubleshoot slipping grub screws easily.

-

-

-

The assembly with the micro switch attaches to the right side of the frame.

-

Be sure to run wiring through the channel and be careful to not damage it while tightening.

-

-

-

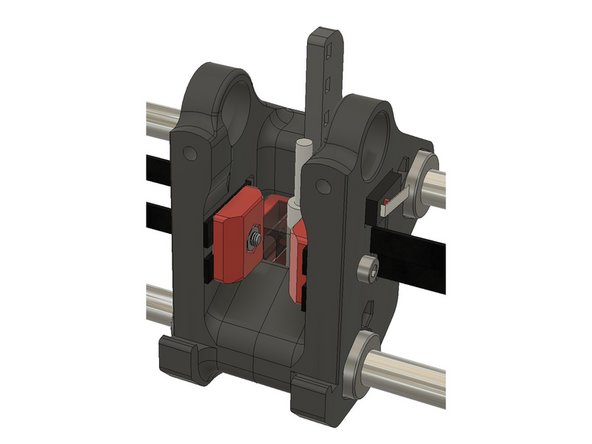

Ensure the two halves mate cleanly or you can have twist along the X axis.

-

Clean up parts with a hobby knife or small file if necessary.

-

-

-

Insert wisdom here.

-

-

-

Be careful not to over-tighten screws into plastic.

-

-

-

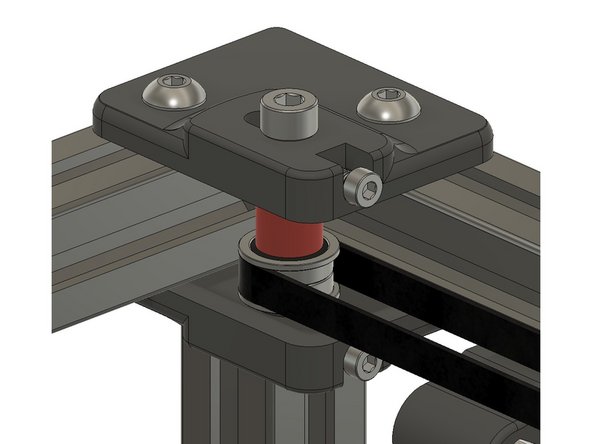

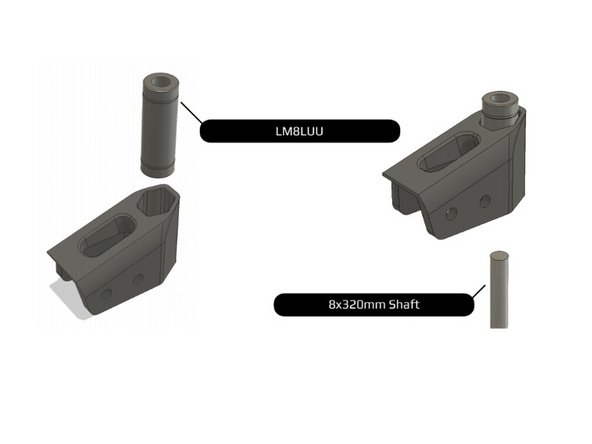

LM8LUU bearing should fit snugly.

-

You can use a c-clamp or similar tool to apply a slow and steady force to slide the bearing in if necessary.

-

-

-

Insert wisdom here.

-

-

-

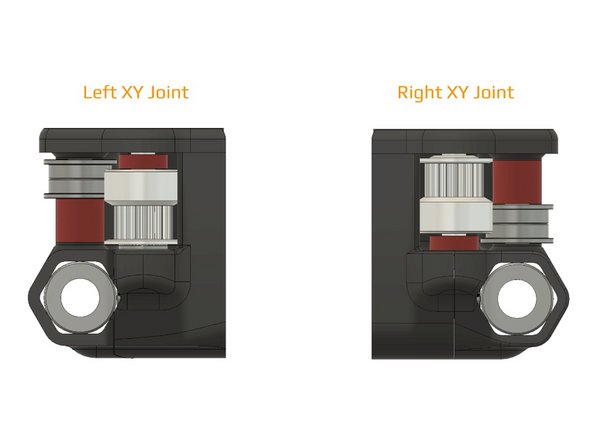

Double check that your spacers and pulleys are located and oriented correctly.

-

-

-

Be careful not to crack the carriage pieces when inserting the bearings.

-

-

-

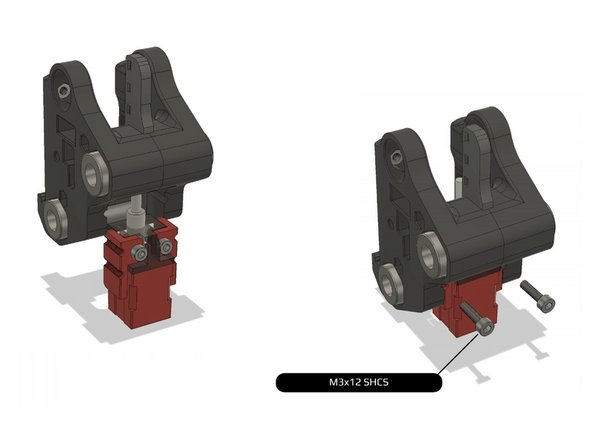

The M3 nuts for securing the toolhead can fall out. They can be added later if necessary. Or secure them in place with a short spare M3 bolt temporarily.

-

-

-

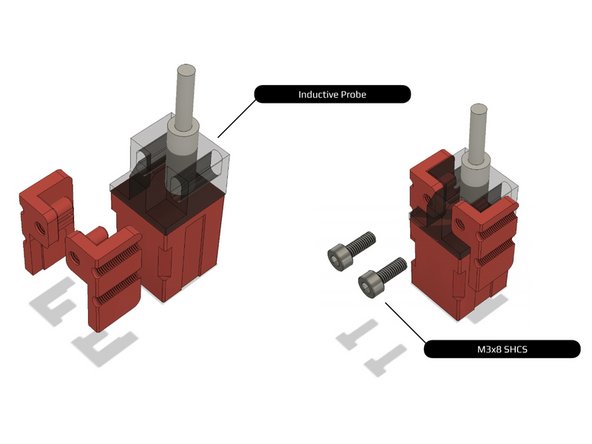

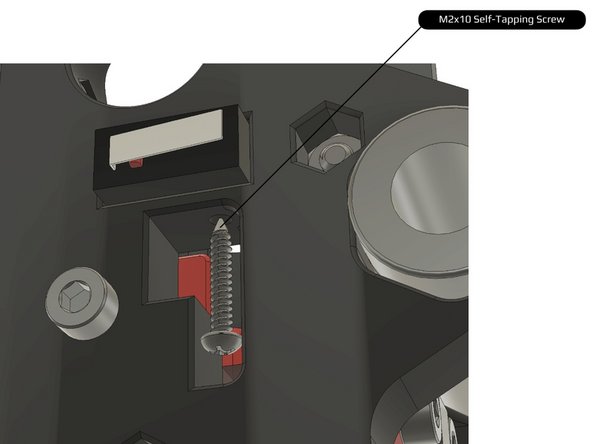

If the probe tabs did not print cleanly, you may need to substitute M2 hardware, clean up the part with a hobby knife, or reprint the pieces.

-

-

-

Insert wisdom here.

-

-

-

Insert wisdom here.

-

-

-

Be sure to wire switch in the NC position.

-

-

-

Be sure to lube the bearings before adding the 8mm rods.

-

-

-

Be sure to add lube to the bearings before assembly.

-

-

-

Ensure smooth movement on both axis before tightening down to the frame.

-

-

-

Wait until you run your belts before tightening the tensioners.

-

Do not overtighten the M5 bolts. The F695 bearings should spin freely.

-

-

-

Insert wisdom here.

-

-

-

Study the belt path.

-

Best practice is to run one belt before cutting. Use this belt to measure the other belt to the exact same length (by tooth count). Leave at least 1 inch (2-3cm) spare on one side so you can tighten by hand easily.

-

-

-

Start at the carriage. Set the belt flush to the edge and tighten the belt retainer.

-

-

-

Run the belts to the X/Y joints. The toothed side should run against the 20t pulleys. The smooth side should run against the flanged bearings.

-

-

-

Run one belt to the front idler/tensioner and back to the X/Y joint.

-

-

-

Continue running both belts to the rear.

-

One belt will engage the drive pulley.

-

Run both belts across the rear of the frame.

-

Run the other belt through the drive gear on the other corner.

-

Use paper clips or zip ties to help force the belt along the correct path as necessary.

-

-

-

Run the belts down the other side through the X/Y joint and front idler.

-

-

-

Finish the run at the carriage.

-

Double check that your belts both follow the correct path.

-

Ensure tensioners on both sides are completely loose.

-

If you cut both belts to the exact same length, pull both of them tight and ensure the same length extend beyond the X carriage.

-

Tuck spare belt back into the carriage.

-

-

-

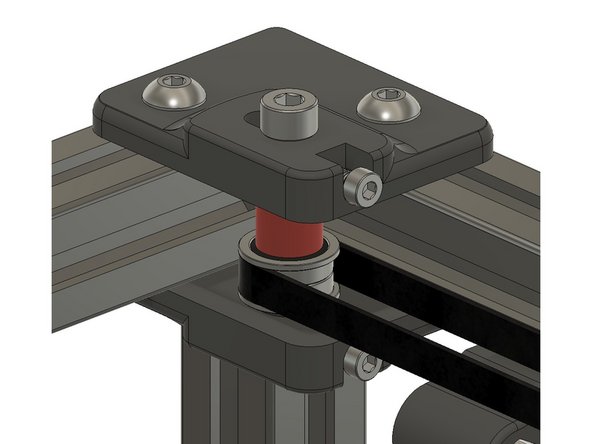

If you opt out of using dampeners, you may need to adjust or rotate the 20t pulley.

-

-

-

Do not over-tension the 110mm belt loop.

-

Apply loctite to the grub screws.

-

-

-

Double-check your assembly.

-

-

-

Insert wisdom here.

-

-

-

Distance shown is from the front of the printer.

-

Use calipers to measure placement.

-

-

-

Insert wisdom here.

-

-

-

Use calipers to measure placement.

-